AI in Manufacturing Operations

AI as an Operations Tool, Not a Science Project

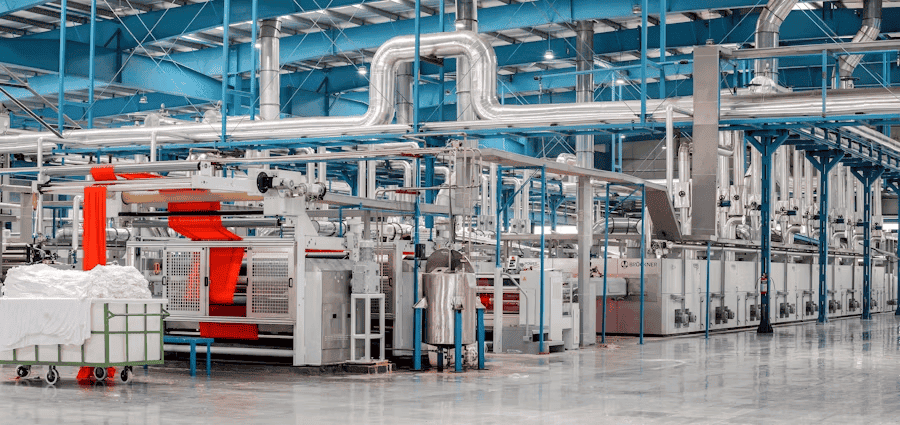

Cut downtime, reduce scrap, stabilize quality, and smooth schedules—often without buying new equipment

Executive Overview – AI as an Operations Tool, Not a Science Project

Most mid-market plants aren't asking for "AI." They're asking for more throughput with the same people and machines, fewer surprises, and orders out the door on time.

The good news: AI has finally moved out of the lab and onto the plant floor. Mid-sized manufacturers are using it to cut unplanned downtime, reduce scrap, stabilize quality, and smooth schedules—often without buying new equipment. Industry studies on "Industry 4.0" programs report 30–50% reductions in machine downtime and 10–30% throughput gains when analytics and AI are applied to the right levers.

For a Midwest job shop, plastics molder, or food manufacturer, that doesn't mean robots taking over the plant. It means predictive maintenance instead of firefighting, vision systems watching every part instead of spot checks, schedulers with AI co-pilots instead of spreadsheets, and operators supported by real-time insights instead of gut feel alone. The plants that move first here will run leaner, hit OTIF more consistently, and be harder to displace—without turning everything upside down.

Why Manufacturing Operations Are a Strong Fit for AI

Manufacturing operations are a sweet spot for AI because:

Processes are repeatable

Lines, cells, and work centers repeat the same tasks thousands of times.

Signals already exist

You likely have PLCs, SCADA, MES, quality records, and maintenance logs—even if they're messy.

KPIs are clear

OEE, scrap, changeover time, and on-time delivery give a direct way to measure impact.

Constraints are real

Legacy machines, union rules, food safety, and regulatory constraints all demand practical, not theoretical, solutions.

AI is especially well-suited for:

- Predicting failures before they cause downtime

- Catching defects early, automatically

- Squeezing more throughput out of bottlenecks

- Smarter production schedules that adjust to reality

- Better promise dates and on-time delivery

- Inventory and WIP levels tuned to real demand

For mid-market plants, the goal isn't a "lights-out factory." It's a smarter version of the plant you already have, where your people make better, faster decisions because the data is finally working for them.

High-Value AI Use Cases on the Plant Floor and in Planning

Numbers below are typical ranges reported in industry research and case studies; your mileage varies, but they show what's realistic for mid-market manufacturers, not just global giants.

| Category | Use Case | Business Value | Typical Impact Range | Difficulty |

|---|---|---|---|---|

| Maintenance | Predictive maintenance on critical assets | Reduce unplanned downtime, avoid catastrophic failures | Downtime ↓ 30–50%, maintenance cost ↓ 10–40%, OEE ↑ 5–15 pts | Med |

| Quality (Vision) | Automated visual inspection of parts/products | Catch defects early, reduce scrap & rework, lower returns | Scrap/rework ↓ 20–50%, inspection labor ↓ 30–70%; ROI often in 6–12 months | Med–High |

| Production | Bottleneck monitoring & cycle-time optimization | Increase throughput on constraint resources | Throughput ↑ 10–30%, WIP reductions, shorter lead times | Med |

| Scheduling | AI-driven production scheduling & rescheduling | More stable schedule, fewer changeovers, higher on-time delivery | Line capacity ↑ ~20–25%, on-time delivery ↑ 20–50%, planning time ↓ 90%+ | Med–High |

| Planning | Delivery date prediction / promise-date accuracy | Better OTIF, fewer expediting costs | Forecast and delivery-date accuracy ↑ significantly; OTIF ↑ 10–20 pts | Med |

| Quality / Scrap | Process monitoring + video AI for scrap reduction | Reduce scrap, stabilize processes, support root cause analysis | Scrap ↓ 15–40%, faster root cause on defects | Low–Med |

| Energy | Energy load optimization by line/shift | Lower energy cost per unit, reduce peak demand charges | Energy cost ↓ 5–15%, sometimes more in energy-intensive lines | Med |

| Supply Chain | AI-assisted demand forecasting & inventory | Right-size inventory, fewer stockouts and rush fees | Forecast accuracy ↑ (often 10–20 pts), inventory ↓ 10–30% | Med–High |

| Workforce | AI maintenance and setup "co-pilots" | Faster troubleshooting, reduced training time | Troubleshooting time ↓ ~30%, faster ramp of new techs | Low–Med |

Start Small: One Line, One Cell, One Site

The pattern that works in mid-market plants:

- 1. Pick one pain point: Chronic downtime on a bottleneck asset, a quality issue driving scrap or customer complaints, or a planning/scheduling fire drill that happens every week.

- 2. Limit the scope: One line, one cell, or one product family. 60–90 days to prove impact.

- 3. Baseline the metrics: Current OEE, scrap %, changeover time, OTIF, energy per unit, etc.

- 4. Run a focused pilot: Introduce one AI use case (predictive maintenance, vision inspection, smarter scheduling). Involve operators, maintenance, and planners early.

- 5. Scale what works: Once you prove, say, a 15% scrap reduction or 20% downtime reduction on one line, scale to similar lines and sites.

Tools, Platforms & AI Agent Patterns for Manufacturing

You don't have to build everything from scratch. Most mid-market plants assemble a stack from:

1. Industrial Data & IIoT Layer

- Machine connectivity & sensors: retrofitting legacy machines with vibration, temperature, current sensors; pulling data from PLCs, SCADA, and existing HMIs.

- Data collection platforms: on-prem or cloud solutions that store time-series data from machines, plus events from MES/ERP.

2. Analytics, AI & Vision Layer

- Industrial analytics platforms with built-in OEE, downtime, and alerts, plus ML for anomaly detection and predictive maintenance.

- Computer vision stacks for quality inspection, often using off-the-shelf cameras plus AI models tuned to your parts and defects.

- Scheduling & optimization engines that consider changeovers, constraints, labor, and maintenance windows to produce better production plans.

3. Integration into MES / ERP / CMMS

Integrations to:

- Push predicted failures into the CMMS as work orders.

- Update MES with in-line quality results.

- Feed ERP/MRP with more realistic capacity and promise dates.

This is where many mid-market plants need help—glueing new insights into existing workflows.

4. AI "Agent" Patterns for Operators

We're seeing early but promising patterns where AI behaves like a co-worker:

- Maintenance co-pilot: watches sensors, flags likely failures, suggests diagnostics and repair steps, and pre-builds the parts list.

- Scheduling co-pilot: proposes a schedule, flags overloads and late orders, and explains trade-offs.

- Quality co-pilot: highlights drift in defect rates, suggests where to check fixtures, setup, or materials.

- Operations assistant: answers "what happened last time we ran this SKU?" by mining historical data.

The test for any tool or agent: does it make the day easier for supervisors and operators, and does it move a KPI?

Case Studies & Benchmarks (OEE, Downtime, Scrap, On-Time Delivery)

Here's what "good" looks like in the real world:

Auto parts supplier – predictive maintenance

A leading auto parts manufacturer implemented AI-driven predictive maintenance and cut unplanned downtime by ~27%, increasing throughput without adding new machines.

Mixed-model electronics / assembly – Industry 4.0 program

Broad Industry 4.0 efforts across sectors have produced 30–50% reductions in machine downtime and 10–30% throughput gains, alongside labor productivity improvements.

Global manufacturer – AI scheduling

One large manufacturer's AI scheduling initiative yielded roughly 24% more line capacity, 19% higher volume, and a 3.5x increase in on-time deliveries, with schedule planning dropping from hours to minutes.

Food & CPG – computer vision quality

Vision systems in food and brick/ceramics production have improved defect detection, reduced waste and warranty claims, and cut manual inspection time dramatically, often delivering payback in under a year.

Small and mid-sized manufacturers – predictive maintenance

Regional manufacturing support organizations report that AI predictive maintenance can reduce unplanned downtime significantly (often 20–50%) and extend equipment life, making it especially attractive for plants that can't just buy new machines.

Use these not as promises, but as guardrails to size the opportunity for your own lines and plants.

Implementation Playbook – Pilot on One Line / One Cell / One Site

Think in terms of 90 days to prove value, not a multi-year transformation.

Phase 1 (Weeks 1–3): Identify the Right Problem

Pick a single high-impact, narrow problem:

- A bottleneck machine that routinely stops the line

- A chronic defect that drives scrap or rework

- A product family with painful, frequent changeovers

- A line that routinely misses planned output or ship dates

Confirm the business case:

- If you could cut downtime by 30% on this machine, what does that do to throughput and revenue?

- If you knock scrap down 25% on this product, what's the annual savings?

Phase 2 (Weeks 2–5): Baseline & Instrument

Capture a clean baseline for 4–6 weeks:

- OEE (availability, performance, quality)

- Scrap/rework rates by SKU

- Changeover time

- Incident logs and maintenance reports

Instrument what's missing:

- Add low-cost sensors where needed

- Ensure PLC/SCADA/MES tags are available

- Stand up a simple data pipeline if you don't already have one

Phase 3 (Weeks 4–8): Build and Integrate the Pilot

Implement one AI solution:

- Predictive maintenance model for critical assets

- Vision system on an inspection step

- Scheduling optimizer for a high-variability line

Integrate into existing workflows, e.g.:

- Alerts become CMMS work orders

- Vision failures trigger existing hold/review processes

- Schedules still go through the same supervisor, but now with AI recommendations

Phase 4 (Weeks 8–12): Run, Measure, Decide

Run the AI-enabled process side-by-side with the baseline.

Measure deltas:

- Downtime, scrap, throughput, OTIF, labor hours

Decide:

- Scale (same use case to more lines/sites)

- Adjust (tune model, add sensors, tweak workflows)

- Or kill if the value isn't there

Stakeholders You Need at the Table

- Ops leadership (COO/Head of Operations) – sets priorities and removes roadblocks

- Plant manager / production supervisors – own day-to-day reality

- Maintenance leader & techs – critical for predictive maintenance and reliability

- Quality manager – owns specs, sampling plans, customer impact

- IT/OT / controls engineers – ensure secure and reliable data flows

- Frontline operators – the people who have to live with the new tools

If they feel the solution is being "done to them," it will stall. If they feel it solves their headaches, it will spread.

Risks, Safety & Change Management

The Human Side

Common fears on the plant floor:

- "Is this here to watch me or replace me?"

- "If the AI says something different than my experience, who wins?"

- "What happens when it's wrong?"

You address these by:

- Positioning AI as a better gauge, not a replacement for judgment.

- Keeping humans in the loop: AI recommends; operators and supervisors decide.

- Making sure early pilots make operators' lives easier (fewer breakdowns, clearer priorities, less reactive chaos).

Safety and Regulatory Reality

Especially in food, pharma, and regulated sectors:

- AI must respect existing safety interlocks and procedures.

- Recommendations must not bypass lock-out/tag-out or sanitation protocols.

- Systems need clear fall-back to manual in case of doubt or failure.

Any vendor or partner that hand-waves safety or compliance should be a non-starter.

2–5 Year Outlook: The AI-Augmented Plant

In the next few years, the "AI-augmented" mid-market plant will likely look like this:

- Downtime is increasingly forecast, not discovered. Predictive maintenance and digital twins help maintenance teams plan work in quieter windows, boosting OEE and smoothing schedules.

- Quality is monitored in real time. Computer vision and process analytics flag drift early, cutting scrap and protecting customers—and turning quality into a competitive weapon rather than a cost center.

- Schedulers and planners are AI-assisted. Instead of wrestling spreadsheets, they use tools that simulate scenarios, surface bottlenecks, and recommend plans—especially valuable with tight labor and complex mixes.

- Operators have better tools, not more reports. AI systems push clear, prioritized actions (e.g., "Check this bearing this shift," "This run is trending toward a defect pattern—check setup now") rather than static dashboards.

- Mid-market manufacturers that adopt early will look a lot more like "lighthouses" than laggards—capturing the productivity uplift that large leaders are already seeing from AI and advanced analytics.

How a Strategic AI Partner Helps

Most mid-market manufacturers don't need a massive transformation program. They need:

A good partner should:

- Speak operations language first, AI language second.

- Be comfortable working with legacy equipment, unions, and safety constraints.

- Commit to hard metrics: OEE, downtime, scrap, OTIF, cost per unit.

- Help you build internal capability so you're not dependent forever.

Ready to Scope Your 90-Day AI Operations Pilot?

Run a focused 90-day AI operations pilot on one line or cell. Start by mapping where downtime, scrap, or missed shipments are costing you the most—and then design a pilot that proves real savings in one quarter.

In 20 minutes, we'll have a conversation to understand your manufacturing context, assess whether there's a fit for AI augmentation in your operations, and determine if a 90-day Sprint makes sense for your situation.

Apply for Your 90-Day Sprint

Due to the hands-on nature of the Sprint, I work with a limited number of mid-market leaders each year. Tell me about your situation and I'll be in touch within 24 hours.

Current availability: Accepting applications for Q1 2026 engagements.

What to expect:

- ✓ 20-minute conversation to understand your context

- ✓ Quick assessment of AI opportunities in your operations

- ✓ Honest take on what's worth pursuing (and what's not)

- ✓ No obligation, just clarity on your next steps

Satisfaction guarantee: If the call doesn't provide value, I'll refund your time with actionable next steps at no charge.

Contact Information

Key Takeaways

- AI in manufacturing isn't about robots taking over your plant—it's about cutting downtime, scrap, and chaos with the machines you already have.

- Mid-market plants are using AI for predictive maintenance, vision-based quality, and smarter scheduling, seeing 20–50% reductions in unplanned downtime and double-digit OEE gains.

- The winning pattern: one problem, one line, 90 days—baseline the metrics, plug in a focused AI use case, and measure the impact before scaling.

- Success depends less on fancy models and more on integration and change management—getting data off your machines and building tools operators actually want to use.

- Plants that start now will look like "AI lighthouses" in 2–5 years, with higher throughput, more reliable delivery, and fewer firefights than their peers.